Composite

HIGH-QUALITY EXTRUDED POLYSTYRENE XPS FOAM PRODUCTS FROM JACKON INSULATION

For more than 35 years, JACKON Insulation has been successfully manufacturing high-quality materials made of extruded polystyrene XPS foam. As an innovative company committed to continuous product improvements, JACKON Insulation has built a reputation as a strong and reliable supplier in a fiercely competitive market. With products such as JACKODUR® XPS foam, JACKON ranks among the most ground-breaking companies in the industry.

The JACKON Insulation name is synonymous with high-quality and sustainable products. This has been achieved over time by giving close attention to the careful selection of raw materials and suppliers to ensure the development of energy-efficient solutions.

JACKODUR® for industrial applications is a business unit tailored specifically to the needs of the processing industry. JACKON Insulation develops customised solutions for its customers, designing composite elements for use in the building industry and vehicle manufacturing sectors.

JACKODUR® for industrial applications is manufactured at JACKON Insulation’s German facility in Mechau, employing a production process monitored by consistent quality controls.

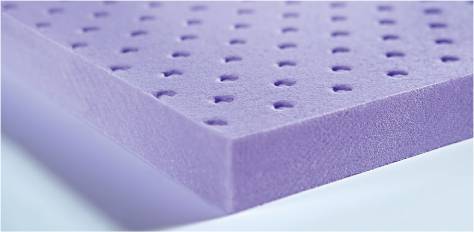

JACKODUR® KF

JACKODUR® KF extruded polystyrene XPS foam products are highly durable, dimensionally stable, water-repellent, thermally insulating and lightweight. These qualities make them the ideal product for a variety of applications. The JACKODUR® KF extruded polystyrene XPS foam product line is available in a number of variants, including strength and finish, depending on the application and specified requirements.

- JACKODUR® KF 300

- JACKODUR® KF 500

- JACKODUR® KF 700

KEY FEATURES:

- Custom sizes available in small batches

- Choice of compressive strength variants

- Various surface finishes

- Dimensionally stable

- Moisture-resistant

- Superior mechanical properties

- Thickness tolerance +/- 0.15mm

- Easy to work with

- Lightweight

- 100% recyclable

- Low thermal conductivity 0.034 @ 90 days

PRODUCT SPECIFICATIONS:

- Thicknesses from 8 mm to 160 mm produced inline, with a planed surface

- Small batches from 10 m3 available in custom sizes

- Compressive strengths ranging from 300 to 700 kPa, with a bulk density of 30 – 50kg /m3

- Thicknesses from 2.8 mm to 160 mm, board lengths from 1000 mm to 3050 mm, and widths from 460 mm to 1220 mm

BROCHURE DOWNLOAD:

Further details and specifications for this product, download the product brochure:

FINISH OPTIONS:

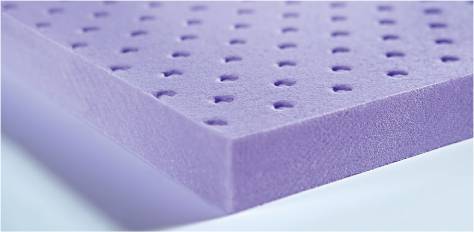

JACKODUR® FT

JACKODUR® FTR

JACKODUR® FTS

JACKODUR® PLUS

JACKODUR PLUS extruded polystyrene XPS foam combines the properties of JACKODUR CFR with significantly reduced thermal conductivity. The thermal insulation of JACKODUR PLUS is improved by up to 27% in comparison to JACKODUR CFR products. JACKODUR PLUS allows a thinner board to be used, resulting in an increase of available space. In addition, the blowing agent used in JACKODUR PLUS has an extremely low GWP (Global Warming Potential), and therefore effectively contributes to climate and environmental protection.

Product Types

- JACKODUR PLUS 300

- JACKODUR PLUS 400

- JACKODUR PLUS 500

KEY FEATURES:

- Custom sizes available in small batches

- Choice of compressive strength variants

- Various surface finishes

- Various surface finishes

- Moisture resistant

- Superior mechanical properties

- Thickness tolerance +/- 0.15mm

- Easy to work with

- Lightweight

- 100% recyclable

- Low thermal conductivity 0.027 @ 90 days

PRODUCT SPECIFICATIONS:

- Thicknesses from 20 mm to 160 mm produced inline, with a planed surface

- Small batches from 10 m3 available in custom sizes

- Compressive strengths ranging from 300 kPa to 500 kPa, with a bulk density of 32 kg to 45 kg /m3

- Thicknesses from 2.8 mm to 160 mm, board lengths from 1000 mm to 3050 mm, and widths from 450 mm to 1500 mm

BROCHURE DOWNLOAD:

Further details and specifications for this product, download the product brochure:

FINISH OPTIONS:

JACKODUR® FT

JACKODUR® FTR

JACKODUR® FTS