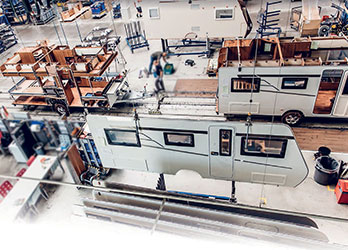

One-stop adhesive solutions for the global RV industry

H.B. Fuller has a proven 100-year history of quality product development and over the years has acquired leading brands to expand its portfolio and expertise. Its adhesive solutions have now become an integral part of almost every kind of finished goods in the marketplace, from electronic devices and building materials to packaging and filters.

The acquisition of Kömmerling in 2017 was a perfect fit for the RV industry, as both companies had already served the market with a complementary range of products. Kömmerling is recognised as one of the first adhesive suppliers in Europe to commercialise 2-component elastic adhesive technology based on MS-polymers.

H.B. Fuller has highly experienced technical and commercial teams in all significant production markets around the world, with Technology Centres of Excellence in

USA, China, India, Germany and Malaysia.This gives customers local access to a global network of experts and all the adhesive and sealant technologies required to build a high-quality vehicle. This extensive product portfolio has been developed and tested in its laboratories across the world to meet the demand from international RV manufacturers. In fact, H.B. Fuller’s customer base includes all the main RV producers in Europe. The company promotes a close collaboration between customers, suppliers and OEMs, and is often involved with new applications from their inception. Adhesives need to create a high quality and durable bond for all elements that come to-

together to create a caravan or motorhome, including the sidewalls, roof, floor, front and rear panels. And of course, these bonds must cope with the challenges of being

used in all climates, in every season. In Europe, this is normally achieved through the use of liquid applied moisture cure polyurethanes. Alternative technology includes 2-component Polyurethanes, mainly used for premium brands, and reactive hot melts, which are more common in the US market. H.B. Fuller supplies both types of adhesive technology.

As 1-component PUR and MS-Polymers need the right level of humidity during the curing process, seasonal differences are a challenge in most markets. For example, in cold winter weather, the curing process will slow down, which can impact the timely supply of parts to the production line. In the worst case scenario, the adhesive may not be fully cured when leaving the production hall. Thankfully, this problem can be overcome by using the elastic material as a 2-component material instead of a 1-component material. This requires the use of a second component containing moisture and will satisfactorily ensure fast and safe curing, no matter what the weather conditions are on site. H.B. Fuller can even create a tailor-made customer solution with different reaction speeds to ensure the production process is as efficient and predictable as possible.

2-component MS-polymers, such as Körapop 225/2-part, which is developed and produced by Kömmerling in Germany, are environmentally friendly as they are free of isocyanates, PVC, solvents and silicone. They react to a permanent high elastic adhesive line and provide good adhesion on various materials, including metal or plastic parts, painted surfaces and wooded layers.

The adhesive has a fast reaction speed within a temperature range of -40°C up to +90°C and provides a high and fast green strength. It has good UV stability and is available in different colours in side-by-side cartridges for small repair work, or with a bulk feed meter mix machinery equipment for industrial production. H.B. Fuller | KÖMMERLING offers a one-stop solution and can now supply every technology needed for the production of high quality RVs. Every day, it listens and collaborates with its customers to deliver the technical solutions and panel lamination adhesives that help them thrive.

Company profile

H.B. Fuller

From a one-man wallpaper paste shop in Minnesota in 1887, H.B. Fuller has grown into a $3 billion adhesives global leader today. Its recent acquisition of Royal Adhesives and Sealants, including the KÖMMERLING Chemische Fabrik GmbH business, created a unique powerhouse of RV adhesive and sealant expertise, supplying products for every conceivable RV application.

Kömmerling

Headquartered in Pirmasens, some 170 km south west of Frankfurt, and founded in 1897, Kömmerling is a leading international manufacturer of high-quality adhesives and sealants. In this capacity, it has been supplying the RV industry in Europe and beyond for more than 20 years. It became a member of H.B. Fuller’s global network through the company’s acquisition of Royal Adhesives & Sealants in October 2017.