What Materials are Used in Caravan Construction?

A new caravan or motorhome is a big purchase and one you want to make an informed choice about. It’s easy to get carried away looking at flashy features and styling. But you should always remember to pay attention to the important details like what materials the caravan is constructed with. The type and quality of materials will play a significant role in everything from fuel efficiency and insulation to lifespan, maintenance needs and durability in different climates and weather conditions.

There are two main forms of construction that recreational vehicle manufacturers use. The first is the traditional “stick and tin” construction dating back to the 1940s. This involves laying aluminum cladding or composite panels over a timber frame. The second is a newer process that involves assembling composite sandwich panels.

Building caravans with composite sandwich panels is more efficient and increasingly favoured over traditional stick and tin builds by both manufacturers and consumers. This is because caravans built with wood are heavier, harder to clean and more susceptible to rot, water damage and warping. A composite caravan, on the other hand, is incredibly durable, lightweight and resistant to weather.

What is a Composite Caravan Exactly?

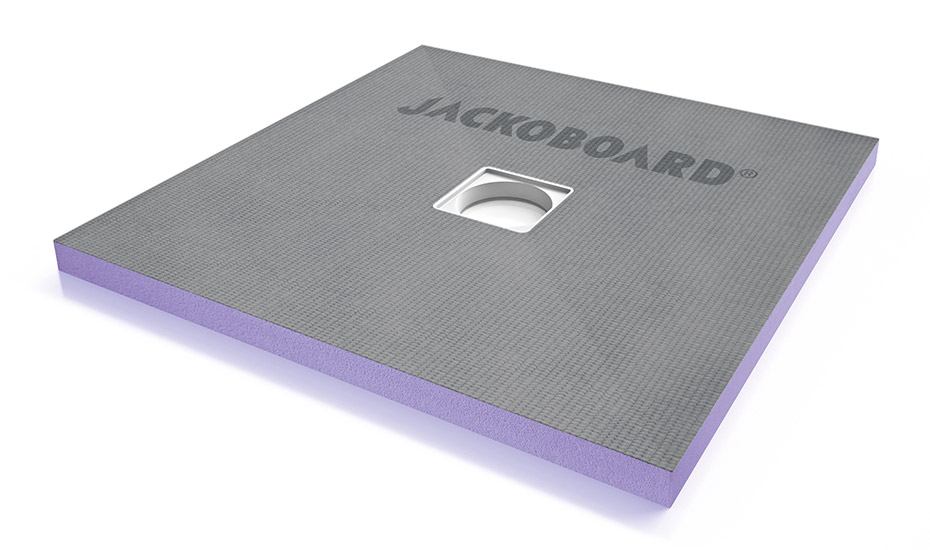

Manufacturers use a type of construction known as ‘composite sandwich panel’ to build the walls, ceiling and floors of a composite caravan. These panels generally consist of two facings and a rigid foam core. Since these panels act as structural elements in the vehicle, must support a variety of loads and operate in a variety of weather conditions, the quality of the materials used to produce them is crucial to the overall performance of the vehicle.

The foam core usually consists of rigid plastic foam, the most suitable being extruded polystyrene XPS foam. Sandwich panels are manufactured by attaching two thin, strong, and stiff composite skins with the XPS foam core between them. The outer layers of a sandwich panel are ideally made from premium fibreglass sheet, which are also rigid, durable, lightweight and aesthetically pleasing.

Composite Caravans – Strong and Lightweight

The structural elements of a caravan must withstand a variety of loads, from vehicle occupants to furniture, fixtures and fittings inside the caravan along with the dynamic forces associated with operating the vehicle itself. These static and dynamic loads must be taken into account when selecting the right materials. Composite sandwich panels are extremely strong in terms of withstanding compression, tension, bending and shear forces associated with vehicle movements.

The high strength-to-weight ratio of XPS foam makes it possible to reduce the amount of frames and inserts used in floor, wall and roof panels whilst offering the same strength and durability. This enables manufacturers to reduce weight while improving the load capacity and rigidity of their vehicles without the need for extra reinforcement.

Each Layer Works Together

The outer composite layers absorb compressive and tensile forces from loading, while the XPS foam core layer is responsible for absorbing shear and dynamic forces created by wind, vibration and torsional stress during driving. The high compressive strength of the core layer material has a stabilising effect on the composite components, ensuring outer layers don’t buckle or crack when subjected to compression.

Each layer of the sandwich panel supports the other in a manner comparable to I-beams. The result is an incredibly high strength-to-weight ratio. Composite panels offer at least the same or even higher level of strength as aluminium panels but with a greater level of stiffness and much lighter weight.

Lightweight Materials Improve Fuel Efficiency

Using lightweight materials offers massive savings in fuel costs over the lifespan of a caravan. Every kilo saved in the construction of any vehicle, whether a caravan or motorhome, results in less energy needed over its lifetime. Composite sandwich panel caravans are more eco-friendly as a result and offer significant cost savings for the consumer.

How XPS Foam Drives Superior Thermal Efficiency

Extruded polystyrene XPS foam has multiple characteristics that make it ideal as a core material in composite sandwich panel construction. XPS foam has a closed cell structure that repels moisture, has excellent insulating properties and high mechanical strength. Using composite sandwich panels with XPS foam cores allow caravan manufacturers to create vehicles with superior thermal insulation characteristics while ensuring a high level of durability and water resistance.

XPS foam is such a good insulator that it’s also used in cold storage buildings and refrigerated trucks transporting perishable goods. For example, a 3cm thick piece of XPS foam has the same U-value (which measures thermal transmittance) as a 17cm thick piece of plywood panel. Using thermally efficient materials like XPS foam reduces energy costs, keeping your caravan comfortable without your heating and air conditioning working as hard.

The Importance of Water Resistance

Moisture is a caravan’s worst enemy. But it’s one that’s impossible to avoid, from wet weather to water vapours released by cooking, showers, drying laundry, people breathing, etc. The key to mitigating the impact of moisture is proper ventilation and the right materials. Composite caravan constructions ensure there are no overlapping wall or roof joins and no opportunity for water to enter the caravan’s framing and rot it, which is what ultimately claims most older wooden caravans.

There are huge variations in how each type of material deals with moisture and water absorption from things like humidity, dew and freeze-thaw cycles. Composite panels with XPS foam core perform the best in all of these areas. XPS foam is unique in being able to tolerate wet environments and performs consistently and predictably in both wet and dry conditions.

Introducing JACKODUR® XPS Foam

JACKODUR® by JACKON INSULATION is an industry leading XPS foam product that is widely used for commercial roof insulation, commercial freezer rooms, refrigerated truck bodies, camper vans, caravans and motorhomes.

- Durable

- Lightweight

- Thermally efficient

- Dimensionally stable

- Moisture-resistant

- 100% recyclable

- Flexible and easy to work with

JACKODUR® XPS foam can be easily bonded with outer layers made from GRP, and aluminium using common polyurethane adhesives. This makes it ideal for composite sandwich panel constructions.

Building Better Caravans with JACKODUR® XPS Foam Boards

For over 35 years, JACKON INSULATION has consistently manufactured high quality insulated products. With a strong focus on the customer, JACKODUR® products can reliably meet the unique needs of manufacturers operating in a variety of industries including the production of caravans and motorhomes.

At Liner, we’re dedicated to supplying manufacturers with the highest quality materials from leading brands like JACKON INSULATION. Contact us today for a quote, product sample, consultation or for more information about JACKODUR® XPS foam products.

Related Questions

How thick do composite sandwich panels need to be?

The thickness of composite sandwich panels in caravan contruction is typically between 30 to 35mm. However, this varies depending on floor type, loads, construction, shape and size.

Why is it so important to insulate a caravan in Australia?

High quality insulation is essential for caravans in Australia as any road trip in the country will find you experiencing vastly different temperatures and climates, from 0 to 40 degrees. Insulation is vital for comfort and to protect the caravan itself.

Do sandwich panels prevent moisture inside the caravan?

High quality, moisture-resistant materials like fibreglass and XPS repel condensation and prevent moisture related issues inside the caravan, ensuring the vehicle lasts longer. Ventilation is also crucial for preventing condensation inside the caravan.